Complete Angle Size Guide: Steel Angle Dimensions & Applications

Understanding steel angle sizes is crucial for engineers, students, and DIY professionals working with structural projects. This comprehensive guide covers everything you need to know about angle dimensions, specifications, and practical applications.

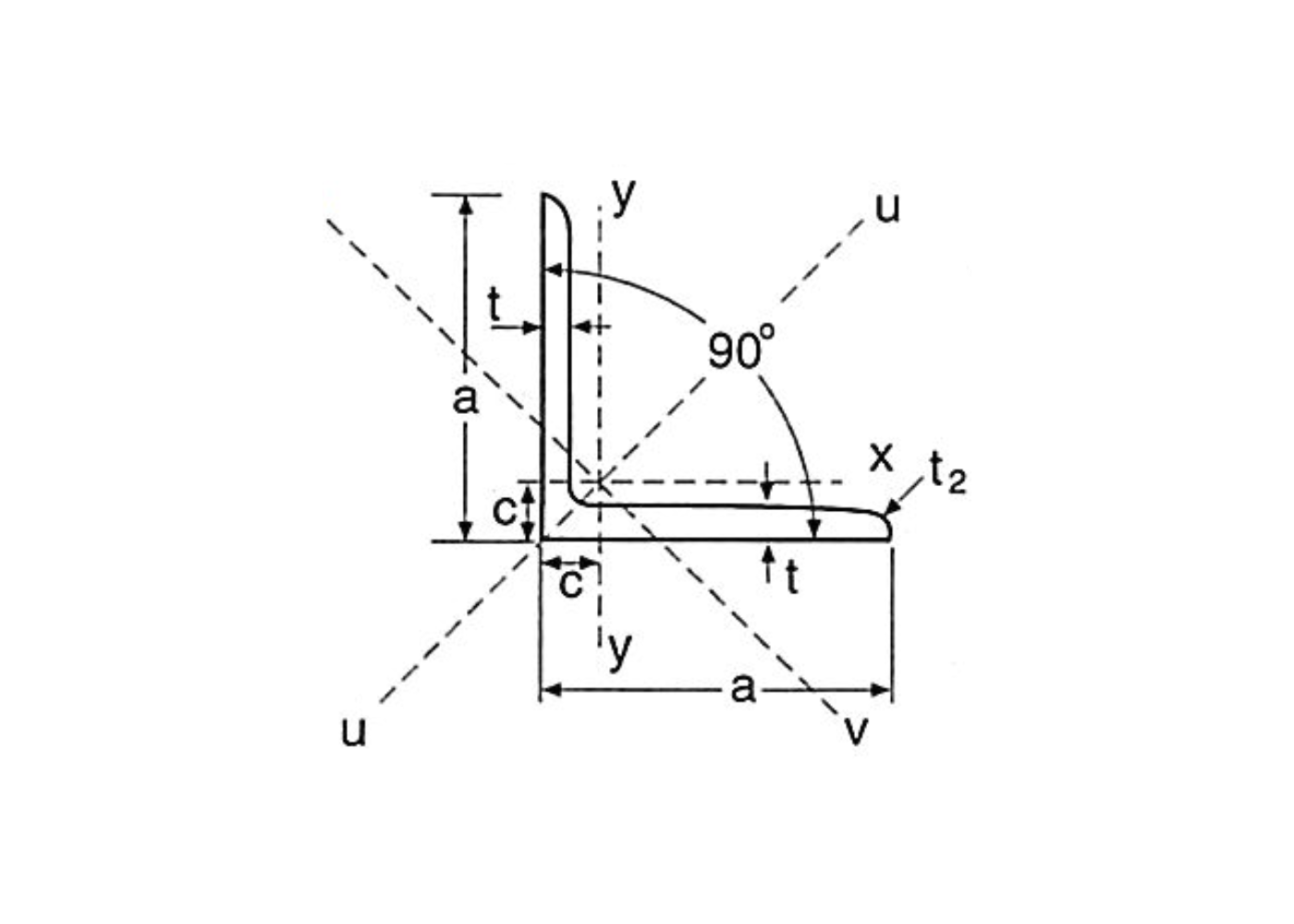

Figure 1: Basic steel angle diagram showing equal leg configuration

Table of Contents

Introduction to Steel Angles

Steel angles, also known as L-shaped steel or angle iron, are fundamental structural components in construction and engineering projects. These versatile profiles consist of two legs joined at a right angle, creating an L-shaped cross-section that provides excellent structural support and versatility in applications.

The importance of understanding angle sizes cannot be overstated - proper selection directly impacts structural integrity, cost efficiency, and project success. Whether you're designing a building frame, fabricating machinery, or working on a DIY project, knowing how to interpret and select the right angle dimensions is essential.

Why This Guide Matters

- Ensures proper structural design and safety

- Helps optimize material costs and weight

- Prevents over-engineering or under-specification

- Provides standardized reference for professionals

- Supports accurate project planning and estimation

Types of Steel Angles

Equal Leg Angles

Equal leg angles have both legs of the same length, creating a symmetrical L-shape. These are the most common type used in construction.

- Symmetrical design for balanced load distribution

- Standard sizes range from 20mm to 200mm

- Commonly used in framework and bracing

Unequal Leg Angles

Unequal leg angles have legs of different lengths, providing specialized load-bearing characteristics for specific applications.

- Asymmetrical design for directional loading

- Used where different leg lengths are advantageous

- Common in specialized structural applications

Standard Dimensions & Sizing

Steel angles are specified using a standard notation system. Understanding this system is crucial for proper selection and ordering. The standard format is: L (Length of leg 1) × (Length of leg 2) × (Thickness)

Dimension Notation Examples

- L50×50×5: Equal leg angle with 50mm legs and 5mm thickness

- L75×50×6: Unequal leg angle with 75mm and 50mm legs, 6mm thickness

- L2×2×1/4: Imperial notation for 2" × 2" × 1/4" angle

Standard Equal Leg Angles (Metric)

| Size (L×L×t) | Leg Length (mm) | Thickness (mm) | Weight (kg/m) | Area (cm²) |

|---|---|---|---|---|

| L20×20×3 | 20 | 3 | 0.91 | 1.16 |

| L25×25×3 | 25 | 3 | 1.12 | 1.43 |

| L30×30×3 | 30 | 3 | 1.36 | 1.74 |

| L40×40×4 | 40 | 4 | 2.42 | 3.08 |

| L50×50×5 | 50 | 5 | 3.77 | 4.80 |

| L60×60×6 | 60 | 6 | 5.42 | 6.91 |

| L75×75×6 | 75 | 6 | 6.85 | 8.73 |

| L90×90×7 | 90 | 7 | 9.61 | 12.2 |

| L100×100×8 | 100 | 8 | 12.2 | 15.5 |

| L125×125×10 | 125 | 10 | 19.0 | 24.2 |

| L150×150×12 | 150 | 12 | 27.3 | 34.8 |

| L200×200×16 | 200 | 16 | 48.5 | 61.8 |

Standard Unequal Leg Angles (Metric)

| Size (L×L×t) | Long Leg (mm) | Short Leg (mm) | Thickness (mm) | Weight (kg/m) |

|---|---|---|---|---|

| L40×25×4 | 40 | 25 | 4 | 1.93 |

| L50×30×5 | 50 | 30 | 5 | 2.93 |

| L60×40×5 | 60 | 40 | 5 | 3.65 |

| L75×50×6 | 75 | 50 | 6 | 5.44 |

| L100×65×7 | 100 | 65 | 7 | 8.77 |

| L125×75×8 | 125 | 75 | 8 | 12.2 |

| L150×90×10 | 150 | 90 | 10 | 18.2 |

| L200×100×12 | 200 | 100 | 12 | 27.3 |

Material Specifications

Steel angles are manufactured from various steel grades, each with specific properties suited for different applications. Understanding these materials helps ensure proper selection for your project requirements.

Common Steel Grades

-

A36 Steel:

General construction steel with good weldability

-

A572 Grade 50:

High-strength, low-alloy structural steel

-

S235/S275:

European standard structural steels

-

304/316 Stainless:

Corrosion-resistant for harsh environments

Material Properties

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|

| A36 | 250 | 400-550 |

| A572-50 | 345 | 450 |

| S235 | 235 | 360-510 |

| S275 | 275 | 410-560 |

Real-World Applications & Examples

Steel angles find application across numerous industries and project types. Understanding these applications helps in selecting the appropriate size and grade for specific requirements.

Construction & Building

- • Building frame connections

- • Roof truss supports

- • Stair stringers

- • Equipment mounting brackets

- • Architectural details

Industrial & Manufacturing

- • Machine frames and guards

- • Conveyor systems

- • Storage rack construction

- • Platform and walkway framing

- • Equipment foundations

DIY & General Use

- • Garden structures and gates

- • Furniture frames

- • Garage and workshop projects

- • Repair and reinforcement

- • Custom fabrication projects

Typical Size Selections by Application

Weight Calculations & Formulas

Calculating the weight of steel angles is essential for structural design, shipping estimates, and cost calculations. Here are the fundamental formulas and practical examples.

Basic Weight Formula

For steel angles, the weight per meter can be calculated using:

Where: A = long leg length (mm), B = short leg length (mm), t = thickness (mm), 7.85 = steel density (kg/dm³)

Example Calculation

For L50×50×5 angle:

- A = 50mm, B = 50mm, t = 5mm

- Weight = [(50 + 50 - 5) × 5 × 7.85] / 1000

- Weight = [95 × 5 × 7.85] / 1000

- Weight = 3,728.75 / 1000

- Weight = 3.73 kg/m

Quick Reference

Use our angle weight calculator for instant results:

- • Enter dimensions directly

- • Supports metric and imperial units

- • Calculates total weight for any length

- • Includes material cost estimation

Selection Guidelines

Choosing the right angle size involves considering load requirements, span distances, connection methods, and cost factors. Follow these guidelines for optimal selection.

Key Selection Factors

- Load Requirements: Consider both static and dynamic loads

- Span Distance: Longer spans require larger sections

- Connection Type: Bolted vs. welded connections

- Environmental Conditions: Corrosion resistance needs

- Cost Considerations: Balance material cost vs. performance

- Availability: Standard sizes are more readily available

- Fabrication Requirements: Cutting, drilling, welding needs

- Building Codes: Compliance with local regulations

Recommended Sizes by Application

| Application | Typical Size Range | Common Grade | Notes |

|---|---|---|---|

| Light framing/brackets | L25×25×3 to L40×40×4 | A36 | For non-structural applications |

| General construction | L50×50×5 to L75×75×6 | A36/S235 | Most common structural sizes |

| Heavy structural work | L100×100×8 to L200×200×16 | A572-50/S275 | For major load-bearing elements |

| Marine/corrosive environments | Variable | 316 Stainless | Higher initial cost, lower maintenance |

Frequently Asked Questions

Equal leg angles have both legs of the same length, creating a symmetrical L-shape that distributes loads evenly. Unequal leg angles have legs of different lengths, which is useful when different load-bearing characteristics are needed in each direction or when one leg needs to fit into a specific space constraint.

Use the formula: Weight (kg/m) = [(A + B - t) × t × 7.85] / 1000, where A and B are leg lengths in mm, t is thickness in mm, and 7.85 is steel density. For convenience, use our angle weight calculator for instant results.

A36 steel is suitable for most general construction applications. Use A572 Grade 50 for higher strength requirements. For corrosive environments, consider stainless steel grades like 304 or 316. Always consult structural engineering requirements and local building codes.

Yes, steel angles are typically available in standard lengths of 6m (20 feet) or 12m (40 feet), though this can vary by supplier and region. Custom lengths can often be ordered, but standard lengths are more cost-effective and readily available.

Yes, steel angles can be both welded and bolted. Welding provides stronger connections but requires skilled labor and proper equipment. Bolted connections are easier to assemble and disassemble but may require larger connection areas. The choice depends on application requirements, access, and available skills.

Corrosion prevention methods include: using galvanized angles for outdoor applications, applying protective coatings (paint, epoxy), choosing stainless steel for harsh environments, ensuring proper drainage to prevent water accumulation, and regular maintenance inspections.

Share This Guide

Bookmark This Resource

This comprehensive angle size guide serves as an essential reference for all your steel angle selection needs. Bookmark this page for quick access to dimensions, weights, and specifications.