Aluminium Angle Sizes PDF - Complete Reference Guide

Comprehensive guide to aluminium angle sizes with downloadable PDF charts, technical specifications, and practical applications for engineers, students, and construction professionals.

Table of Contents

- 1. Introduction to Aluminium Angles

- 2. Standard Aluminium Angle Sizes

- 3. Weight Charts and Calculations

- 4. Technical Specifications

- 5. Real-World Applications

- 6. Selection and Usage Guide

- 7. Installation and Fabrication Tips

- 8. Aluminium vs Steel Angles

- 9. Frequently Asked Questions

- 10. Conclusion and Resources

Introduction to Aluminium Angles

Aluminium angles are L-shaped structural members widely used in construction, engineering, and manufacturing applications. Understanding their dimensions, weights, and properties is crucial for proper selection and design. This comprehensive guide provides detailed information about standard aluminium angle sizes, complete with downloadable reference charts.

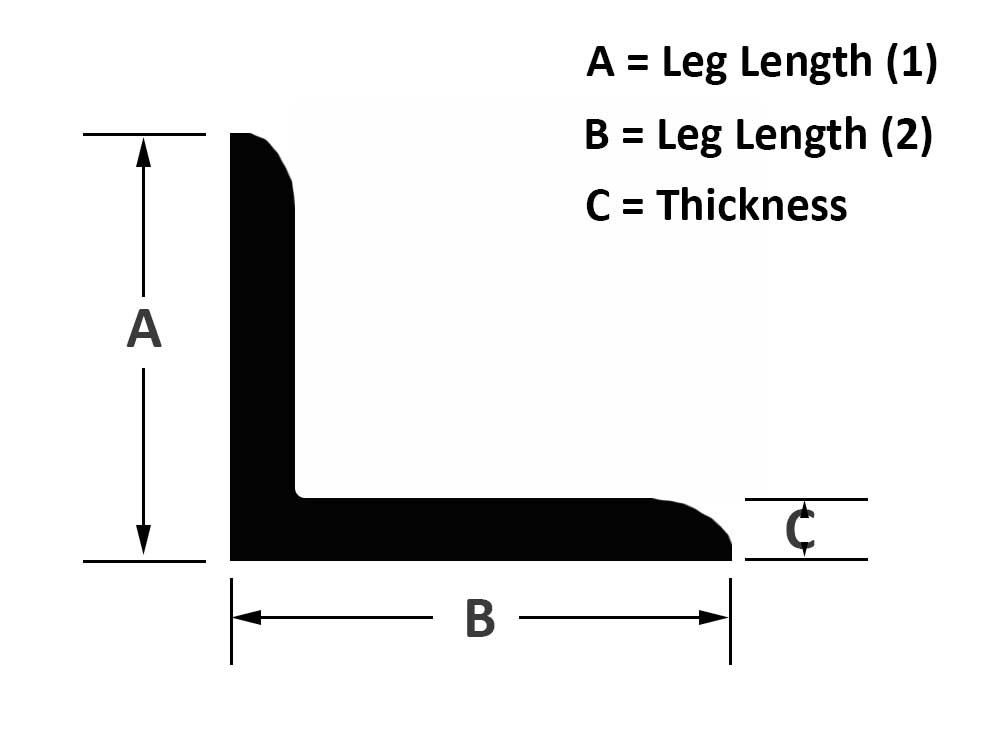

Figure 1: Aluminium Angle Cross-Section Diagram

Key Benefits of Aluminium Angles

- Lightweight: Approximately 1/3 the weight of steel

- Corrosion Resistant: Natural oxide layer provides protection

- High Strength-to-Weight Ratio: Excellent structural properties

- Easy to Fabricate: Can be cut, drilled, and welded easily

- Recyclable: Environmentally friendly material

- Non-Magnetic: Suitable for electronic applications

Standard Aluminium Angle Sizes

Aluminium angles are available in two main configurations: equal leg angles and unequal leg angles. The following tables provide comprehensive size information for both types.

Equal Leg Aluminium Angles

| Size (A × A) | Thickness (t) | Weight (kg/m) | Cross-Sectional Area (cm²) | Moment of Inertia (cm⁴) |

|---|---|---|---|---|

| 20 × 20 | 3 | 0.32 | 0.12 | 0.08 |

| 25 × 25 | 3 | 0.41 | 0.15 | 0.15 |

| 25 × 25 | 4 | 0.53 | 0.19 | 0.19 |

| 30 × 30 | 3 | 0.49 | 0.18 | 0.26 |

| 30 × 30 | 4 | 0.64 | 0.24 | 0.33 |

| 40 × 40 | 3 | 0.66 | 0.24 | 0.61 |

| 40 × 40 | 4 | 0.86 | 0.32 | 0.78 |

| 40 × 40 | 5 | 1.05 | 0.39 | 0.94 |

| 50 × 50 | 3 | 0.83 | 0.31 | 1.19 |

| 50 × 50 | 4 | 1.08 | 0.40 | 1.54 |

| 50 × 50 | 5 | 1.33 | 0.49 | 1.87 |

| 60 × 60 | 4 | 1.30 | 0.48 | 2.68 |

| 60 × 60 | 5 | 1.60 | 0.59 | 3.26 |

| 60 × 60 | 6 | 1.89 | 0.70 | 3.82 |

| 70 × 70 | 5 | 1.88 | 0.70 | 5.23 |

| 70 × 70 | 6 | 2.22 | 0.82 | 6.14 |

| 80 × 80 | 6 | 2.56 | 0.95 | 9.12 |

| 80 × 80 | 8 | 3.35 | 1.24 | 11.8 |

| 100 × 100 | 8 | 4.25 | 1.57 | 22.8 |

| 100 × 100 | 10 | 5.24 | 1.94 | 27.8 |

Figure 2: Equal Leg Angle Dimension Notation

Unequal Leg Aluminium Angles

| Size (A × B) | Thickness (t) | Weight (kg/m) | Cross-Sectional Area (cm²) | Moment of Inertia XX (cm⁴) | Moment of Inertia YY (cm⁴) |

|---|---|---|---|---|---|

| 30 × 20 | 3 | 0.41 | 0.15 | 0.19 | 0.07 |

| 40 × 25 | 3 | 0.53 | 0.20 | 0.40 | 0.12 |

| 40 × 25 | 4 | 0.69 | 0.26 | 0.51 | 0.15 |

| 50 × 30 | 4 | 0.86 | 0.32 | 0.98 | 0.35 |

| 50 × 30 | 5 | 1.05 | 0.39 | 1.18 | 0.42 |

| 60 × 40 | 4 | 1.08 | 0.40 | 1.77 | 0.77 |

| 60 × 40 | 5 | 1.33 | 0.49 | 2.15 | 0.93 |

| 60 × 40 | 6 | 1.57 | 0.58 | 2.52 | 1.08 |

| 80 × 40 | 6 | 1.95 | 0.72 | 5.12 | 1.28 |

| 80 × 60 | 6 | 2.28 | 0.84 | 6.33 | 3.47 |

| 100 × 50 | 6 | 2.44 | 0.90 | 11.2 | 2.89 |

| 100 × 75 | 8 | 3.78 | 1.40 | 17.8 | 10.1 |

| 125 × 75 | 8 | 4.32 | 1.60 | 29.5 | 12.8 |

| 150 × 90 | 10 | 6.48 | 2.40 | 64.2 | 27.8 |

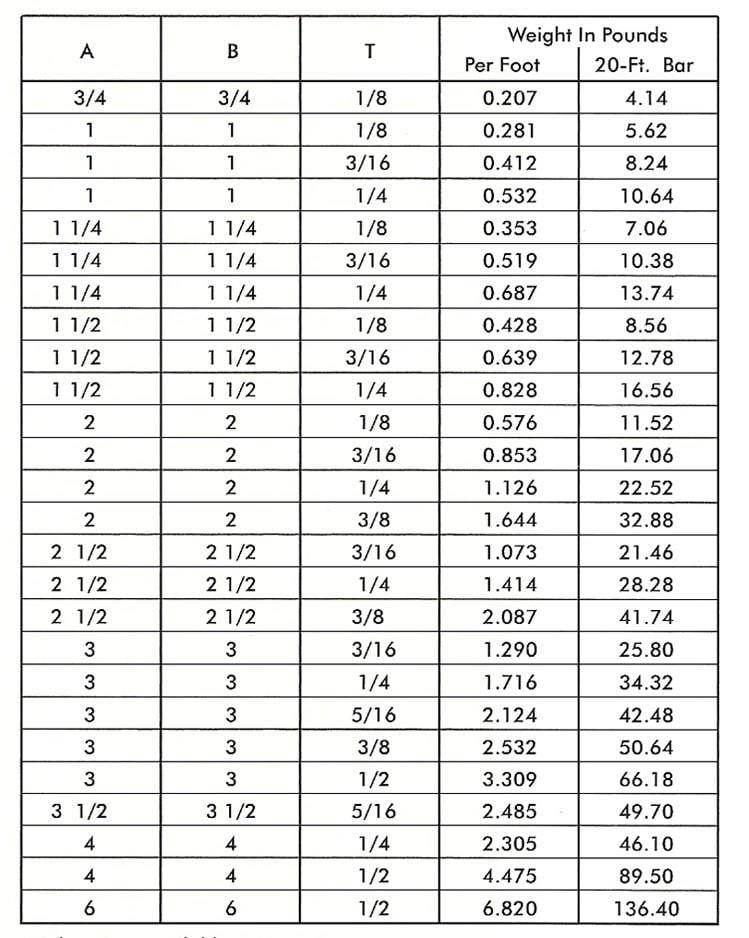

Weight Charts and Calculations

Understanding the weight of aluminium angles is essential for structural calculations, transportation planning, and cost estimation. The weight calculation formula for aluminium angles is:

Weight Calculation Formula

Weight (kg/m) = [(A + B - t) × t] × 0.00271

Where: A & B = leg dimensions (mm), t = thickness (mm), 0.00271 = density factor for aluminium

Figure 3: Comprehensive Aluminium Angle Weight Chart

Quick Reference Weight Chart

Common Equal Leg Angles

- 25×25×3mm: 0.41 kg/m

- 40×40×4mm: 0.86 kg/m

- 50×50×5mm: 1.33 kg/m

- 60×60×6mm: 1.89 kg/m

- 80×80×8mm: 3.35 kg/m

- 100×100×10mm: 5.24 kg/m

Common Unequal Leg Angles

- 40×25×4mm: 0.69 kg/m

- 50×30×5mm: 1.05 kg/m

- 60×40×6mm: 1.57 kg/m

- 80×60×6mm: 2.28 kg/m

- 100×75×8mm: 3.78 kg/m

- 150×90×10mm: 6.48 kg/m

Technical Specifications

Aluminium angles are manufactured according to various international standards. Understanding these specifications is crucial for proper material selection and design.

Material Properties

| Property | 6061-T6 | 6063-T5 | 5052-H32 | Units |

|---|---|---|---|---|

| Density | 2.70 | 2.70 | 2.68 | g/cm³ |

| Tensile Strength | 310 | 214 | 228 | MPa |

| Yield Strength | 276 | 172 | 193 | MPa |

| Elastic Modulus | 68.9 | 68.9 | 70.3 | GPa |

| Elongation | 12 | 12 | 12 | % |

| Hardness (Brinell) | 95 | 60 | 60 | HB |

Manufacturing Standards

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- EN 755: European standard for aluminum and aluminum alloy extruded profiles

- JIS H4100: Japanese Industrial Standard for aluminum and aluminum alloy extruded profiles

- AS/NZS 1866: Australian/New Zealand standard for aluminum and aluminum alloy extruded products

Tolerance Standards

Typical Tolerances (ASTM B221)

- Leg Length: ±0.8mm for dimensions ≤50mm, ±1.6mm for dimensions >50mm

- Thickness: ±10% or ±0.25mm (whichever is greater)

- Length: +6mm/-0mm for cut lengths

- Straightness: 1.3mm per meter maximum

Real-World Applications

Aluminium angles are versatile structural components used across numerous industries. Their lightweight nature and corrosion resistance make them ideal for various applications.

Construction & Architecture

- • Window and door frames

- • Curtain wall systems

- • Structural framing

- • Roof support systems

- • Staircase railings

- • Facade cladding support

Marine & Transportation

- • Boat deck framing

- • Trailer construction

- • Truck body frames

- • Ship superstructures

- • Railway car components

- • Aircraft interior structures

Industrial & Manufacturing

- • Machine frames

- • Conveyor systems

- • Support brackets

- • Equipment enclosures

- • Assembly fixtures

- • Platform structures

DIY & Home Projects

- • Garden structures

- • Shelving systems

- • Workbench frames

- • Greenhouse construction

- • Deck railings

- • Custom brackets

Case Study: Lightweight Building Frame

A recent commercial building project required a lightweight yet strong frame for a glass facade system. The engineering team selected 80×80×6mm equal leg aluminium angles for the primary structure.

Aluminium: 2.56 kg/m

Steel equivalent: 7.6 kg/m

66% weight reduction

Reduced foundation loads

Lower transportation costs

Faster installation

25-year warranty

No painting required

Superior weather resistance

Selection and Usage Guide

Selecting the right aluminium angle size depends on several factors including load requirements, span length, environmental conditions, and budget considerations.

Selection Criteria

1. Load Requirements

Consider both dead loads (permanent) and live loads (temporary). Use structural engineering principles to calculate required section modulus.

2. Span Length

Longer spans require larger sections to prevent excessive deflection. Follow deflection limits (typically L/250 for general construction).

3. Environmental Conditions

Marine environments may require 5000 series alloys for superior corrosion resistance. Standard 6000 series suitable for most applications.

4. Connection Methods

Consider bolt sizes and spacing requirements. Minimum edge distances and center-to-center spacing must be maintained.

Size Selection Chart

| Application Type | Light Duty | Medium Duty | Heavy Duty | Structural |

|---|---|---|---|---|

| Decorative/Trim | 25×25×3 | 30×30×3 | 40×40×4 | N/A |

| Support Brackets | 40×40×4 | 50×50×5 | 60×60×6 | 80×80×8 |

| Frame Members | 50×50×5 | 60×60×6 | 80×80×8 | 100×100×10 |

| Load Bearing | 60×60×6 | 80×80×8 | 100×100×10 | 125×125×12 |

Installation and Fabrication Tips

Proper fabrication and installation techniques ensure optimal performance and longevity of aluminium angle structures.

Cutting and Machining

- Saw Cutting: Use carbide-tipped blades with 80-120 teeth for clean cuts

- Drilling: Use sharp HSS or carbide drills with proper cutting fluid

- Deburring: Remove all burrs to prevent stress concentrations

- Surface Prep: Clean with solvent before assembly

Joining Methods

- Mechanical: Bolts, screws, rivets - most common method

- Welding: TIG welding preferred for structural applications

- Adhesive: Structural adhesives for specific applications

- Hybrid: Combination methods for optimal performance

Important Safety Considerations

- • Always use appropriate PPE when cutting or machining

- • Ensure proper ventilation when welding aluminium

- • Use aluminum-specific tools to prevent contamination

- • Follow local building codes and engineering standards

- • Consider thermal expansion in long runs

Aluminium vs Steel Angles

Understanding the differences between aluminium and steel angles helps in making informed material selection decisions.

| Property | Aluminium | Steel | Advantage |

|---|---|---|---|

| Weight | 2.7 g/cm³ | 7.8 g/cm³ | Aluminium (65% lighter) |

| Strength | 200-400 MPa | 400-600 MPa | Steel |

| Strength-to-Weight | High | Medium | Aluminium |

| Corrosion Resistance | Excellent | Poor (requires coating) | Aluminium |

| Cost | Higher | Lower | Steel |

| Fabrication | Easy | Easy | Equal |

| Recyclability | 95% efficient | 70% efficient | Aluminium |

| Thermal Conductivity | High | Medium | Depends on application |

When to Choose Each Material

Choose Aluminium When:

- • Weight is critical

- • Corrosion resistance needed

- • Long-term maintenance costs matter

- • Non-magnetic properties required

- • Appearance is important

- • Environmental sustainability is priority

Choose Steel When:

- • Maximum strength is required

- • Initial cost is primary concern

- • High temperature applications

- • Heavy-duty structural loads

- • Traditional construction methods

- • Welding is primary joining method

Frequently Asked Questions

6061 aluminium is stronger and more versatile, with higher tensile strength (310 MPa vs 214 MPa). It's better for structural applications. 6063 is more suitable for architectural applications due to better surface finish and easier extrusion. 6061 is heat-treatable to higher strengths, while 6063 is primarily used in T5 or T6 tempers for decorative applications.

Load capacity depends on the application (compression, tension, bending). For bending: Moment capacity = Section modulus × Allowable stress. For compression: Use buckling formulas considering length and end conditions. Always consult structural engineering resources or professionals for critical applications. Safety factors of 2-4 are typically applied.

Yes, aluminium angles can be welded using TIG (GTAW) or MIG (GMAW) processes. TIG welding provides better control and quality for structural applications. Proper joint preparation, shielding gas (pure argon), and aluminum-specific filler rods are essential. Post-weld heat treatment may be required for some applications.

Maximum span depends on load, angle size, and deflection limits. As a rough guide: 25×25×3mm can span 0.5m with light loads, 50×50×5mm can span 1.5m, and 100×100×10mm can span 3-4m. Always perform proper structural calculations considering actual loads, safety factors, and deflection limits (typically L/250).

Use isolation methods: 1) Insert non-conductive materials (plastic washers, gaskets) between dissimilar metals, 2) Use stainless steel fasteners instead of regular steel, 3) Apply protective coatings, 4) Use aluminum-compatible fasteners, 5) Ensure proper drainage to prevent water accumulation at joints.

Common treatments include: 1) Mill finish (as-extruded), 2) Anodizing (clear, bronze, black), 3) Powder coating (various colors), 4) Painting, 5) Brushed finish, 6) Polished finish. Anodizing provides excellent corrosion resistance and appearance. Powder coating offers color options and additional protection.

Conclusion and Resources

This comprehensive guide provides essential information about aluminium angle sizes, specifications, and applications. Understanding these details helps in making informed decisions for your projects, whether you're an engineer, student, or DIY enthusiast.

Key Takeaways

- • Aluminium angles offer excellent strength-to-weight ratio and corrosion resistance

- • Standard sizes range from 20×20mm to 200×200mm for equal leg angles

- • Weight calculation: [(A + B - t) × t] × 0.00271 kg/m

- • 6061-T6 alloy recommended for structural applications

- • Proper fabrication techniques ensure optimal performance

- • Consider environmental conditions and load requirements when selecting

Related Calculator Tools

Angle Weight Calculator

Calculate weight of various angle profiles

Beam Calculator

Structural beam analysis and calculations

Steel Weight Calculator

Calculate weights of steel sections

Material Calculator

General material quantity calculations

Bookmark this resource for quick reference or download the complete PDF guide for offline use.

Download Complete Guide